In the rapidly evolving energy storage landscape, selecting the right battery supplier and manufacturing model is as critical as choosing the battery chemistry itself. Businesses looking for custom battery solutions often encounter the terms OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer). Understanding the distinction between these two models is paramount to ensuring your project’s success, efficiency, and cost-effectiveness.

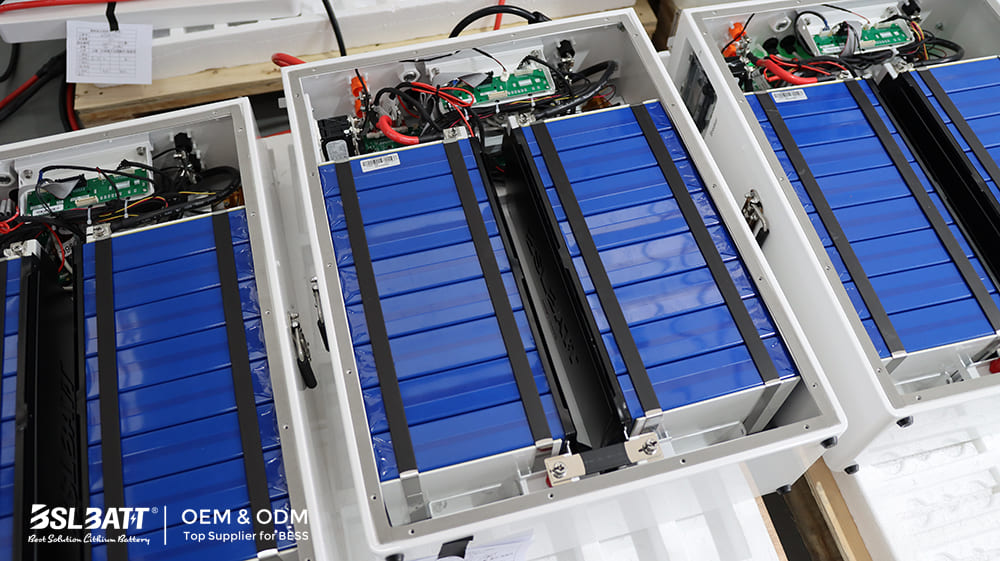

At BSLBATT, with 13+ years of experience in lithium battery manufacturing, we specialize in providing high-quality battery solutions, particularly for energy storage applications. We work closely with clients to determine whether an OEM or ODM approach best fits their unique requirements.

This article will break down the core differences between OEM and ODM battery manufacturing, discuss their respective advantages and disadvantages, and guide you in choosing the optimal path for your specific energy storage needs.

What is OEM Battery Manufacturing?

OEM, or Original Equipment Manufacturing, in the battery industry means that we, as the manufacturer (BSLBATT), produce batteries strictly according to your specific design, technical specifications, and intellectual property (IP).

- You drive the design: You come to us with a fully developed or detailed battery design, including cell specifications, mechanical structure, BMS requirements, enclosure design, and performance parameters.

- We execute the manufacturing: BSLBATT uses our manufacturing expertise, quality control processes, and supply chain to produce batteries precisely as you’ve designed them.

- You own the IP: The design and technical specifications belong to you.

Choosing an OEM battery manufacturer like BSLBATT allows you to create a truly unique product tailored exactly to your application’s demands, especially when off-the-shelf or standard designs don’t meet your specific energy storage requirements (e.g., unique form factors, extreme environmental conditions, specific communication protocols).

What is ODM Battery Manufacturing?

ODM, or Original Design Manufacturing, is a different approach. In this model, BSLBATT designs and manufactures the battery product ourselves, often leveraging our existing proven designs, platforms, or modular components.

- We offer the design: You select a battery product from our existing catalog or a base design that we have developed.

- You customize (optionally): You might request minor modifications to the existing design (e.g., branding, specific connectors, software tweaks), but the core design remains ours.

- You brand and sell: You market and sell the finished product under your own brand name.

- We own the original IP: The core design and underlying technology belong to BSLBATT.

Opting for an ODM battery solution from BSLBATT is typically faster and more cost-effective, as it eliminates the need for extensive ground-up design work. This is often suitable for customers who need a reliable, standard battery solution quickly for applications where minor customization is sufficient.

OEM vs ODM Batteries: A Comparison for Energy Storage Projects

Let’s compare the two models across key factors relevant to deploying batteries in energy storage systems (ESS):

Design & Customization Level

OEM: Highest level of customization. You dictate every detail. Essential for highly specialized ESS applications with unique space, weight, or integration constraints.

ODM: Limited to moderate customization of existing BSLBATT designs. Suitable when a standard battery platform closely matches your ESS needs.

Intellectual Property (IP) Ownership

OEM: You own the IP of the specific design you provide.

ODM: BSLBATT owns the original design IP. You license or purchase the right to sell the finished product under your brand.

Development Time & Cost

OEM: Higher upfront investment in R&D and tooling, longer development cycle. Required when no existing solution fits.

ODM: Lower upfront cost, significantly faster time-to-market as the core design exists. Ideal for quicker deployment of standard ESS solutions.

Design Risk

OEM: The primary design risk (performance validation, potential issues) lies with you.

ODM: BSLBATT has already validated the core design, reducing your design risk significantly.

Supplier Relationship

OEM: More collaborative and deeply involved technical partnership.

ODM: More transactional, focused on selecting and receiving existing products.

Ideal for Energy Storage Applications?

OEM: Best for pioneering ESS products, integrating batteries into completely new systems, or meeting highly specific performance niches.

ODM: Excellent for standard residential, commercial, or small-scale grid storage products where cost and speed are priorities, and an existing reliable design from BSLBATT meets the requirements.

Advantages & Disadvantages: Weighing Your Options

Understanding the trade-offs helps clarify the best fit for your battery solution needs.

Advantages of OEM Battery Manufacturing

Unique Product: Develop a battery pack specifically optimized for your unique energy storage system, providing a competitive edge.

Full Control: You have complete oversight and control over every aspect of the battery’s specifications and quality.

IP Ownership: Secure your unique design as proprietary technology.

Disadvantages of OEM Battery Manufacturing

Higher Investment: Requires significant financial outlay for R&D, design, and tooling.

Longer Timeline: Development and validation take considerably more time than using an existing design.

Requires Expertise: You need robust internal technical capability to design and specify the battery correctly.

Advantages of ODM Battery Manufacturing

Speed to Market: Get your battery product to market much faster by using BSLBATT’s pre-designed and validated solutions.

Lower Cost: Avoid high R&D and tooling costs associated with ground-up design.

Reduced Risk: Rely on BSLBATT’s proven design reliability and manufacturing quality.

Disadvantages of ODM Battery Manufacturing

Limited Customization: Flexibility is restricted to minor modifications of existing designs.

Less Uniqueness: Your competitors might potentially source similar core designs from the same manufacturer.

No Design IP Ownership: You don’t own the rights to the original battery design itself.

Choosing the Right Path with BSLBATT

So, for your energy storage battery project, how do you decide between OEM and ODM? Consider these questions:

- How unique does your battery need to be? (If highly unique -> OEM)

- What is your budget for battery development? (If limited upfront budget -> ODM)

- What is your required timeline to market? (If urgent -> ODM)

- What is your internal battery design expertise? (If limited -> ODM is easier)

- How critical is owning the design IP? (If critical -> OEM)

At BSLBATT, we don’t just manufacture; we partner with you. We can help you analyze your project requirements, understand the trade-offs, and determine whether our OEM battery manufacturing capabilities or our reliable ODM battery solutions are the best fit to achieve your energy storage goals. We offer a range of residential solar batteries, C&I ESS, LFP battery solutions, BESS battery packs and have the flexibility to support both models.

BSLBATT products meet multiple international safety certification standards such as IEC 62619, IEC 62040, UL1973, CE, etc., and can provide reliable OED or ODM services.

Conclusion

Both OEM and ODM battery manufacturing models offer distinct advantages, serving different business needs and project requirements. OEM provides maximum customization and IP ownership at higher cost and time investment, while ODM offers speed and cost-efficiency by leveraging existing, validated designs.

For businesses in the energy storage sector, choosing the right battery manufacturer and model is a strategic decision that impacts everything from product performance and safety to market competitiveness. By understanding the core differences between OEM and ODM, you are better equipped to make an informed choice.

BSLBATT is here to be your trusted partner, whether you require a fully customized OEM battery solution or a reliable, proven ODM battery pack for your energy storage application. Let’s discuss how our expertise can power your next project.

Ready to Explore Your Battery Manufacturing Options?

Frequently Asked Questions (FAQ)

Q1: Can BSLBATT provide both OEM and ODM battery services?

A: Yes, BSLBATT offers both OEM and ODM manufacturing services for various lithium battery applications, with a strong focus on energy storage solutions. We work with clients to determine the most suitable approach.

Q2: What kind of energy storage projects typically use the OEM approach?

A: Energy storage projects requiring unique sizes or shapes (e.g., fitting into specific enclosures), highly specialized performance characteristics, or integration with proprietary systems often benefit from an OEM approach.

Q3: If I choose ODM from BSLBATT, does that mean my battery will be identical to others?

A: While the core design comes from our existing platforms, we can often incorporate minor customizations like specific connectors, branding, software configurations, or packaging to differentiate your product.

Q4: Which model (OEM or ODM) is faster for developing a new energy storage battery product?

A: ODM is generally much faster as it utilizes existing and validated designs, significantly reducing the development and testing time compared to a ground-up OEM design.

Q5: Does OEM or ODM affect the battery’s performance in my energy storage system?

A: The choice of OEM vs ODM relates to the manufacturing and design process, not necessarily the inherent quality or chemistry (like LFP or NMC). However, an optimized OEM design could yield slightly better performance tailored to a very specific niche, while a well-designed ODM from a reputable manufacturer like BSLBATT offers reliable, proven performance.

Post time: May-23-2025