When devices need a long-lasting, high-performance LifePo4 battery pack, they need to balance each cell.  Why LifePo4 battery pack needs battery balancing? LifePo4 batteries are subject to many characteristics such as overvoltage, undervoltage, overcharge and discharge current, thermal runaway and battery voltage imbalance. One of the most important factors is cell imbalance, which changes the voltage of each cell in the pack over time, thereby rapidly reducing battery capacity. When the LifePo4 battery pack is designed to use multiple cells in series, it is important to design the electrical characteristics to consistently balance the cell voltages. This is not only for the performance of the battery pack, but also to optimize the life cycle. The need for doctrine is that battery balancing occurs before and after the battery is built and must be done throughout the battery’s life cycle in order to maintain optimal battery performance! The use of battery balancing allows us to design batteries with higher capacity for applications because balancing allows the battery to achieve a higher state of charge (SOC). You can imagine connecting many LifePo4 Cell units in series as if you were pulling a sled with many sled dogs. The sled can only be pulled with maximum efficiency if all the sled dogs are running at the same speed. With four sled dogs, if one sled dog runs slowly, then the other three sled dogs must also reduce their speed, thus reducing efficiency, and if one sled dog runs faster, it will end up pulling the load of the other three sled dogs and hurting itself. Therefore, when multiple LifePo4 cells are connected in series, the voltage values of all cells should be equal in order to obtain a more efficient LifePo4 battery pack.

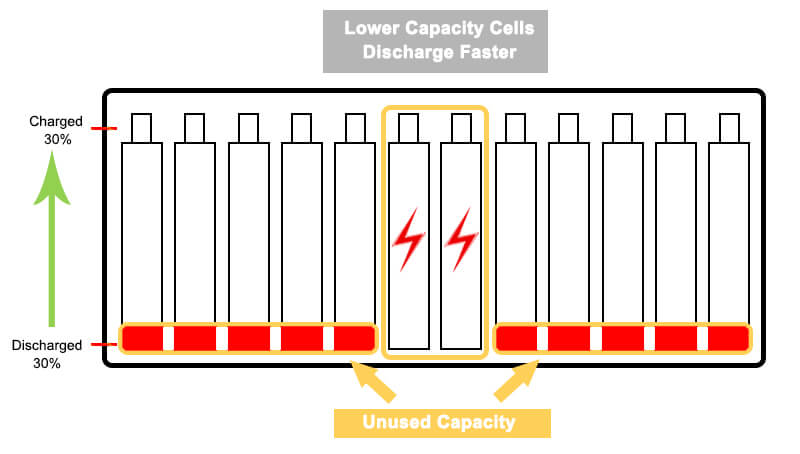

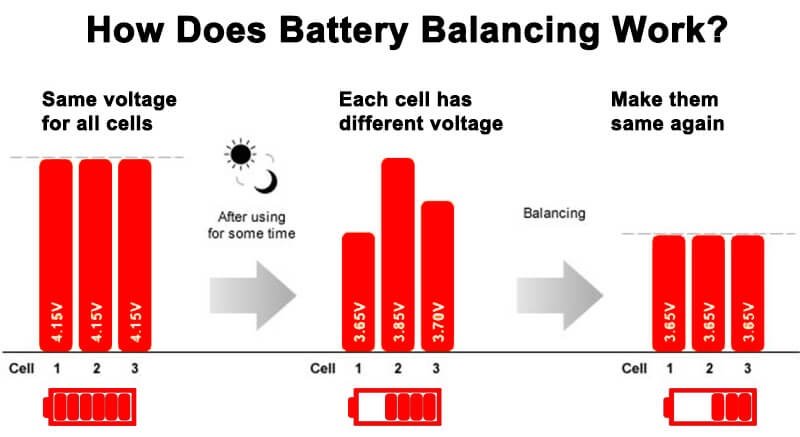

Why LifePo4 battery pack needs battery balancing? LifePo4 batteries are subject to many characteristics such as overvoltage, undervoltage, overcharge and discharge current, thermal runaway and battery voltage imbalance. One of the most important factors is cell imbalance, which changes the voltage of each cell in the pack over time, thereby rapidly reducing battery capacity. When the LifePo4 battery pack is designed to use multiple cells in series, it is important to design the electrical characteristics to consistently balance the cell voltages. This is not only for the performance of the battery pack, but also to optimize the life cycle. The need for doctrine is that battery balancing occurs before and after the battery is built and must be done throughout the battery’s life cycle in order to maintain optimal battery performance! The use of battery balancing allows us to design batteries with higher capacity for applications because balancing allows the battery to achieve a higher state of charge (SOC). You can imagine connecting many LifePo4 Cell units in series as if you were pulling a sled with many sled dogs. The sled can only be pulled with maximum efficiency if all the sled dogs are running at the same speed. With four sled dogs, if one sled dog runs slowly, then the other three sled dogs must also reduce their speed, thus reducing efficiency, and if one sled dog runs faster, it will end up pulling the load of the other three sled dogs and hurting itself. Therefore, when multiple LifePo4 cells are connected in series, the voltage values of all cells should be equal in order to obtain a more efficient LifePo4 battery pack.  The nominal LifePo4 battery is rated at only about 3.2V, but in home energy storage systems, portable power supplies, industrial, telecom, electric vehicle and microgrid applications, we need much higher than the nominal voltage. In recent years, rechargeable LifePo4 batteries have played a critical role in power batteries and energy storage systems due to their light weight, high energy density, long life, high capacity, fast charging, low self-discharge levels and environmental friendliness. Cell balancing ensures that the voltage and capacity of each LifePo4 cell are at the same level, otherwise, the range and lifetime of the LiFePo4 battery pack will be greatly reduced, and the battery performance will be degraded! Therefore, LifePo4 cell balance is one of the most important factors in determining the quality of the battery. During operation, a little voltage gap will occur, but we can keep it within an acceptable range by means of cell balancing. During balancing, the higher capacity cells undergo a full charge/discharge cycle. Without cell balancing, the cell with the slowest capacity is a weak point. Cell balancing is one of the core functions of the BMS, along with temperature monitoring, charging and other functions that help maximize pack life. Other reasons for battery balancing: LifePo4 battery pcak incomplete energy use Absorbing more current than the battery is designed for or shorting out the battery is most likely to cause premature battery failure. When a LifePo4 battery pack is discharging, weaker cells will discharge faster than healthy cells, and they will reach minimum voltage faster than other cells. When a cell reaches minimum voltage, the entire battery pack is also disconnected from the load. This results in an unused capacity of battery pack energy. Cell degradation When a LifePo4 cell is overcharged even a little over its suggested worth the effectiveness and also life process of the cell gets reduced. As an example a minor increase in charging voltage from 3.2V to 3.25V will break down the battery faster by 30%. So if cell balancing is not accurate also minor overcharging will decrease the battery life time. Incomplete Charging of a Cell Pack LifePo4 batteries are billed at a continuous current of in between 0.5 and also 1.0 rates. The LifePo4 battery voltage rises as the charging proceeds to come to a head when completely billed after that consequently falls. Think about three cells with 85 Ah, 86 Ah, and 87 Ah respectively and 100 percent SoC, and all cells are after that released and also their SoC decreases. You can find out swiftly that cell 1 ends up being the first to run out of energy given that it has the lowest capability. When power is put on the cell packs as well as the very same existing is flowing via the cells, once again, cell 1 hangs back throughout charging and might be taken into consideration fully charged as the various other two cells are completely charged. This means that cells 1 have a reduced Coulometric Effectiveness (CE) due to the cell’s self-heating that results in cell inequality. Thermal Runaway The most awful point that can take place is thermal runaway. As we understand lithium cells are very sensitive to overcharging as well as over discharging. In a pack of 4 cells if one cell is 3.5 V while the various other are 3.2 V the charge will certainly billing all the cells together because they are in series and also it will bill the 3.5 V cell to greater than advised voltage because the various other batteries are still need charging.This leads to thermal runaway when the price of inner heat generation surpasses the rate at which the warm can be released.This causes the LifePo4 battery pack to become thermally uncontrolled. What triggers is Cell unbalancing in battery packs? Now we understand why keeping all the cells balanced in a battery pack is essential. Yet to address the problem appropriately we should know why the cells obtain unbalanced first hand. As told earlier when a battery pack is created by placing the cells in series it is made sure that all the cells remain in the very same voltage levels. So a fresh battery pack will always have actually balanced cells. Yet as the pack is put into use the cells get out of balance because of the complying with factors. SOC Discrepancy Measuring the SOC of a cell is complicated; hence it is very intricate to gauge the SOC of specific cells in a battery. An optimal cell harmonizing method should match the cells of the same SOC instead of the exact same voltage (OCV) degrees. But since it is almost not possible cells are matched only on voltage terms when making a pack, the variant in SOC may result in a modification in OCV in due course. Interior resistance variant It is extremely difficult to find cells of the same Internal resistance (IR) and as the battery age, the IR of the cell additionally get altered as well as therefore in a battery pack not all cells will have the same IR. As we understand the IR adds to the inner insusceptibility of the cell which determines the current streaming through a cell. Because the IR is varied the current via the cell and also its voltage also gets different. Temperature level The billing and releasing capability of the cell also depends upon the temperature around it. In a significant battery pack like in EVs or solar arrays, the cells are distributed over a waste area and there may be a temperature distinction among the pack itself creating one cell to charge or discharge faster than the remaining cells causing an inequality. From the above factors, it is clear that we can not prevent cells from getting imbalanced throughout the procedure. So, the only remedy is to make use of an exterior system that requires the cells to get balanced once again after they obtain unbalanced. This system is called the Battery Balancing System.

The nominal LifePo4 battery is rated at only about 3.2V, but in home energy storage systems, portable power supplies, industrial, telecom, electric vehicle and microgrid applications, we need much higher than the nominal voltage. In recent years, rechargeable LifePo4 batteries have played a critical role in power batteries and energy storage systems due to their light weight, high energy density, long life, high capacity, fast charging, low self-discharge levels and environmental friendliness. Cell balancing ensures that the voltage and capacity of each LifePo4 cell are at the same level, otherwise, the range and lifetime of the LiFePo4 battery pack will be greatly reduced, and the battery performance will be degraded! Therefore, LifePo4 cell balance is one of the most important factors in determining the quality of the battery. During operation, a little voltage gap will occur, but we can keep it within an acceptable range by means of cell balancing. During balancing, the higher capacity cells undergo a full charge/discharge cycle. Without cell balancing, the cell with the slowest capacity is a weak point. Cell balancing is one of the core functions of the BMS, along with temperature monitoring, charging and other functions that help maximize pack life. Other reasons for battery balancing: LifePo4 battery pcak incomplete energy use Absorbing more current than the battery is designed for or shorting out the battery is most likely to cause premature battery failure. When a LifePo4 battery pack is discharging, weaker cells will discharge faster than healthy cells, and they will reach minimum voltage faster than other cells. When a cell reaches minimum voltage, the entire battery pack is also disconnected from the load. This results in an unused capacity of battery pack energy. Cell degradation When a LifePo4 cell is overcharged even a little over its suggested worth the effectiveness and also life process of the cell gets reduced. As an example a minor increase in charging voltage from 3.2V to 3.25V will break down the battery faster by 30%. So if cell balancing is not accurate also minor overcharging will decrease the battery life time. Incomplete Charging of a Cell Pack LifePo4 batteries are billed at a continuous current of in between 0.5 and also 1.0 rates. The LifePo4 battery voltage rises as the charging proceeds to come to a head when completely billed after that consequently falls. Think about three cells with 85 Ah, 86 Ah, and 87 Ah respectively and 100 percent SoC, and all cells are after that released and also their SoC decreases. You can find out swiftly that cell 1 ends up being the first to run out of energy given that it has the lowest capability. When power is put on the cell packs as well as the very same existing is flowing via the cells, once again, cell 1 hangs back throughout charging and might be taken into consideration fully charged as the various other two cells are completely charged. This means that cells 1 have a reduced Coulometric Effectiveness (CE) due to the cell’s self-heating that results in cell inequality. Thermal Runaway The most awful point that can take place is thermal runaway. As we understand lithium cells are very sensitive to overcharging as well as over discharging. In a pack of 4 cells if one cell is 3.5 V while the various other are 3.2 V the charge will certainly billing all the cells together because they are in series and also it will bill the 3.5 V cell to greater than advised voltage because the various other batteries are still need charging.This leads to thermal runaway when the price of inner heat generation surpasses the rate at which the warm can be released.This causes the LifePo4 battery pack to become thermally uncontrolled. What triggers is Cell unbalancing in battery packs? Now we understand why keeping all the cells balanced in a battery pack is essential. Yet to address the problem appropriately we should know why the cells obtain unbalanced first hand. As told earlier when a battery pack is created by placing the cells in series it is made sure that all the cells remain in the very same voltage levels. So a fresh battery pack will always have actually balanced cells. Yet as the pack is put into use the cells get out of balance because of the complying with factors. SOC Discrepancy Measuring the SOC of a cell is complicated; hence it is very intricate to gauge the SOC of specific cells in a battery. An optimal cell harmonizing method should match the cells of the same SOC instead of the exact same voltage (OCV) degrees. But since it is almost not possible cells are matched only on voltage terms when making a pack, the variant in SOC may result in a modification in OCV in due course. Interior resistance variant It is extremely difficult to find cells of the same Internal resistance (IR) and as the battery age, the IR of the cell additionally get altered as well as therefore in a battery pack not all cells will have the same IR. As we understand the IR adds to the inner insusceptibility of the cell which determines the current streaming through a cell. Because the IR is varied the current via the cell and also its voltage also gets different. Temperature level The billing and releasing capability of the cell also depends upon the temperature around it. In a significant battery pack like in EVs or solar arrays, the cells are distributed over a waste area and there may be a temperature distinction among the pack itself creating one cell to charge or discharge faster than the remaining cells causing an inequality. From the above factors, it is clear that we can not prevent cells from getting imbalanced throughout the procedure. So, the only remedy is to make use of an exterior system that requires the cells to get balanced once again after they obtain unbalanced. This system is called the Battery Balancing System.  How to achieve LiFePo4 battery pack balance? Battery Management System (BMS) Generally LiFePo4 battery pack cannot achieve battery balancing by itself, it can be achieved by battery management system (BMS). The battery manufacturer will integrate the battery balancing function and other protection functions such as charge over voltage protection, SOC indicator, over temperature alarm/protection, etc. on this BMS board. Li-ion battery charger with balancing function Also known as a “balance battery charger”, the charger integrates a balance function to support different batteries with different string counts (e.g. 1~6S). Even if your battery does not have a BMS board, you can charge your Li-ion battery with this battery charger to achieve balancing. Balancing Board When you use a balanced battery charger, you must also connect the charger and your battery to the balancing board by selecting a specific socket from the balancing board. Protection Circuit Module (PCM) The PCM board is an electronic board that is connected to the LiFePo4 battery pack and its main function is to protect the battery and the user from malfunction. To ensure safe use, the LiFePo4 battery must operate under very strict voltage parameters. Depending on the battery manufacturer and chemistry, this voltage parameter varies between 3.2 V per cell for discharged batteries and 3.65 V per cell for rechargeable batteries. the PCM board monitors these voltage parameters and disconnects the battery from the load or charger if they are exceeded. In the case of a single LiFePo4 battery or multiple LiFePo4 batteries connected in parallel, this is easily accomplished because the PCM board monitors the individual voltages. However, when multiple batteries are connected in series, the PCM board must monitor the voltage of each battery. Types of Battery Balancing Various battery balancing algorithms have been developed for LiFePo4 battery pack. It is divided into passive and active battery balancing methods based on battery voltage and SOC.

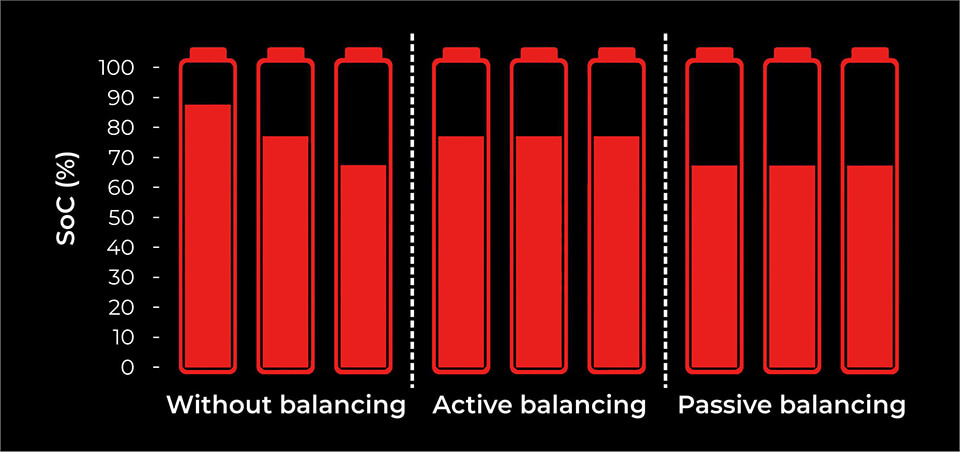

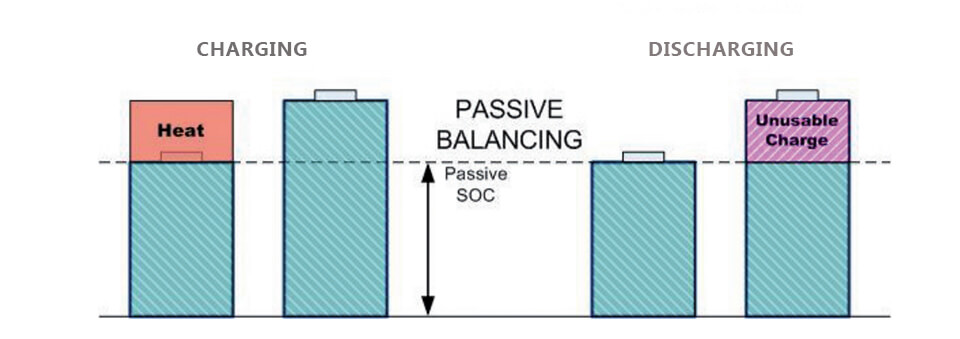

How to achieve LiFePo4 battery pack balance? Battery Management System (BMS) Generally LiFePo4 battery pack cannot achieve battery balancing by itself, it can be achieved by battery management system (BMS). The battery manufacturer will integrate the battery balancing function and other protection functions such as charge over voltage protection, SOC indicator, over temperature alarm/protection, etc. on this BMS board. Li-ion battery charger with balancing function Also known as a “balance battery charger”, the charger integrates a balance function to support different batteries with different string counts (e.g. 1~6S). Even if your battery does not have a BMS board, you can charge your Li-ion battery with this battery charger to achieve balancing. Balancing Board When you use a balanced battery charger, you must also connect the charger and your battery to the balancing board by selecting a specific socket from the balancing board. Protection Circuit Module (PCM) The PCM board is an electronic board that is connected to the LiFePo4 battery pack and its main function is to protect the battery and the user from malfunction. To ensure safe use, the LiFePo4 battery must operate under very strict voltage parameters. Depending on the battery manufacturer and chemistry, this voltage parameter varies between 3.2 V per cell for discharged batteries and 3.65 V per cell for rechargeable batteries. the PCM board monitors these voltage parameters and disconnects the battery from the load or charger if they are exceeded. In the case of a single LiFePo4 battery or multiple LiFePo4 batteries connected in parallel, this is easily accomplished because the PCM board monitors the individual voltages. However, when multiple batteries are connected in series, the PCM board must monitor the voltage of each battery. Types of Battery Balancing Various battery balancing algorithms have been developed for LiFePo4 battery pack. It is divided into passive and active battery balancing methods based on battery voltage and SOC.  Passive Battery Balancing The passive battery balancing technique separates the excess charge from a fully energized LiFePo4 battery through resistive elements and gives all cells a similar charge to the lowest LiFePo4 battery charge. This technique is more reliable and uses fewer components, thus reducing the overall system cost. However, the technology reduces the efficiency of the system as energy is dissipated in the form of heat that generates energy loss. Therefore, this technology is suitable for low power applications.

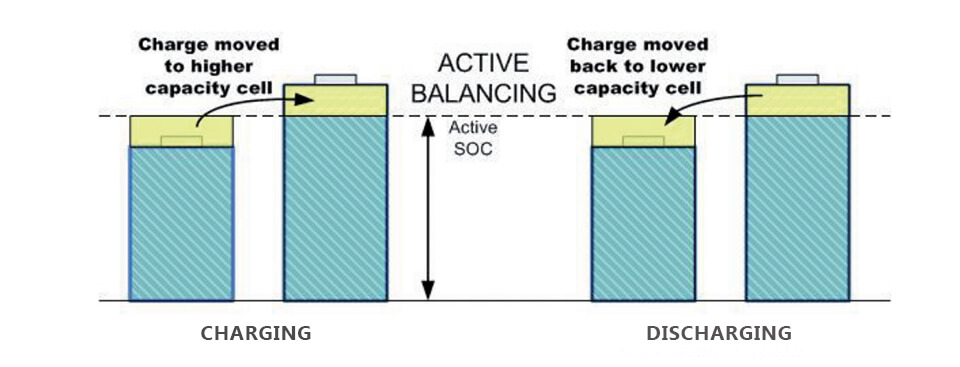

Passive Battery Balancing The passive battery balancing technique separates the excess charge from a fully energized LiFePo4 battery through resistive elements and gives all cells a similar charge to the lowest LiFePo4 battery charge. This technique is more reliable and uses fewer components, thus reducing the overall system cost. However, the technology reduces the efficiency of the system as energy is dissipated in the form of heat that generates energy loss. Therefore, this technology is suitable for low power applications.  Active battery balancing Active charge balancing is a solution to the challenges associated with LiFePo4 batteries. The active cell balancing technique discharges the charge from the higher energy LiFePo4 battery and transfers it to the lower energy LiFePo4 battery. Compared to passive cell balancing technology, this technique saves energy in the LiFePo4 battery module, thus increasing the efficiency of the system, and requires less time to balance between LiFePo4 battery pack cells, allowing for higher charging currents. Even when the LiFePo4 battery pack is at rest, even perfectly matched LiFePo4 batteries lose charge at different rates because the rate of self-discharge varies depending on the temperature gradient: a 10°C increase in battery temperature already doubles the rate of self-discharge. However, active charge balancing can restore cells to equilibrium, even if they are at rest. However, this technique has complex circuitry, which increases the overall system cost. Therefore, active cell balancing is suitable for high power applications. There are various active balancing circuit topologies classified according to energy storage components, such as capacitors, inductors/transformers, and electronic converters. Overall, the active battery management system reduces the overall cost of the LiFePo4 battery pack because it does not require oversizing of the cells to compensate for dispersion and uneven aging among the LiFePo4 batteries. Active battery management becomes critical when old cells are replaced with new cells and there is significant variation within the LiFePo4 battery pack. Since active battery management systems make it possible to install cells with large parameter variations in LiFePo4 battery packs, production yields increase while warranty and maintenance costs decrease. Therefore, active battery management systems benefit the performance, reliability and safety of the battery pack, while helping to reduce costs. Summarize In order to minimise the effects of cell voltage drift, imbalances must be properly moderated. The goal of any balancing solution is to allow the LiFePo4 battery pack to operate at its intended level of performance and to extend its available capacity. Battery balancing is not only important for improving the performance and life cycle of batteries, it also adds a safety factor to LiFePo4battery pack. One of the emerging technologies for improving battery safety and extending battery life. As the new battery balancing technology tracks the amount of balancing required for individual LiFePo4 cells, it extends the life of the LiFePo4 battery pack and enhances overall battery safety.

Active battery balancing Active charge balancing is a solution to the challenges associated with LiFePo4 batteries. The active cell balancing technique discharges the charge from the higher energy LiFePo4 battery and transfers it to the lower energy LiFePo4 battery. Compared to passive cell balancing technology, this technique saves energy in the LiFePo4 battery module, thus increasing the efficiency of the system, and requires less time to balance between LiFePo4 battery pack cells, allowing for higher charging currents. Even when the LiFePo4 battery pack is at rest, even perfectly matched LiFePo4 batteries lose charge at different rates because the rate of self-discharge varies depending on the temperature gradient: a 10°C increase in battery temperature already doubles the rate of self-discharge. However, active charge balancing can restore cells to equilibrium, even if they are at rest. However, this technique has complex circuitry, which increases the overall system cost. Therefore, active cell balancing is suitable for high power applications. There are various active balancing circuit topologies classified according to energy storage components, such as capacitors, inductors/transformers, and electronic converters. Overall, the active battery management system reduces the overall cost of the LiFePo4 battery pack because it does not require oversizing of the cells to compensate for dispersion and uneven aging among the LiFePo4 batteries. Active battery management becomes critical when old cells are replaced with new cells and there is significant variation within the LiFePo4 battery pack. Since active battery management systems make it possible to install cells with large parameter variations in LiFePo4 battery packs, production yields increase while warranty and maintenance costs decrease. Therefore, active battery management systems benefit the performance, reliability and safety of the battery pack, while helping to reduce costs. Summarize In order to minimise the effects of cell voltage drift, imbalances must be properly moderated. The goal of any balancing solution is to allow the LiFePo4 battery pack to operate at its intended level of performance and to extend its available capacity. Battery balancing is not only important for improving the performance and life cycle of batteries, it also adds a safety factor to LiFePo4battery pack. One of the emerging technologies for improving battery safety and extending battery life. As the new battery balancing technology tracks the amount of balancing required for individual LiFePo4 cells, it extends the life of the LiFePo4 battery pack and enhances overall battery safety.

Post time: May-08-2024